Description

Application Procedure

Surface Preparation

- Clean the surface from contaminents such as oil, grease, salts & chlorides using a biodegradable degreaser such as Safeclean BIO 3, followed by a rinse with clean water

- Remove any loose rust, paint and corrosion by abrasive blasting, UHP waterjetting or power tool cleaning.

Paint Application

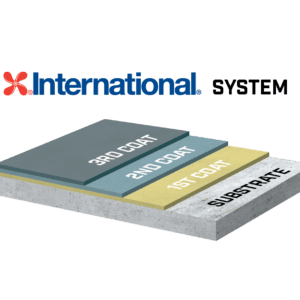

Apply by brush, roller or spray:

| Layer | Product Name | Generic Type | Mix Ratio | Min. Temp. | Dry time @ 25°C | m2/L brush | m2/L spray | Thinner |

| 1st coat | Interbond 201 | 2 comp. abrasion resistant epoxy | 16 : 4 | 5°C | 0,5 hrs | 4,44 | 2,96 | GTA 220 |

| 2nd coat | Interbond 201 | 2 comp. abrasion resistant epoxy | 16 : 4 | 5°C | 2 hrs | 4,44 | 2,96 | GTA 220 |

Find the right application tools in the toolbox for solvent based coatings

Tips

- Do not apply or expose the paint below dew point, above 80% relative humidity, rain or temperatures below 10°C during application or drying.

- Make sure the mixing ratio is correct

- Wait at least 15min. after mixing before applying the paint

- Apply a stripe coat by brush on sharp edges, cavities such as pitting corrosion, in corners and difficult areas to reach by spray

- Do not overcoat a single component system with a 2 component system

- Respect to minimum and maximum overcoating time as per product data sheet

Always read the product technical data sheet and safety data sheet before using the coatings, to be found in the Download section.

Reviews

There are no reviews yet.